A practical guide to avoiding overcurrent issues when installing microinverters

Connecting microinverters to branch circuits

When you’re installing microinverters, it’s critical that the current of the output terminal is taken into consideration when attaching to a branch circuit. Connecting too many inverters to a single branch circuit can lead to the failure of the output terminal. However, the rated current of the microinverter’s output terminal is often overlooked, leaving users to deal with the consequences of overcurrent.

A branch circuit is any circuit that extends beyond the final overcurrent protective device – this includes circuits servicing single motors, and those serving multiple outlets. The maximum number of microinverters you can attach to a branch circuit depends on the parameters of the cables and connectors on that branch, as well as the model of your microinverters., as well as the model of your microinverters.

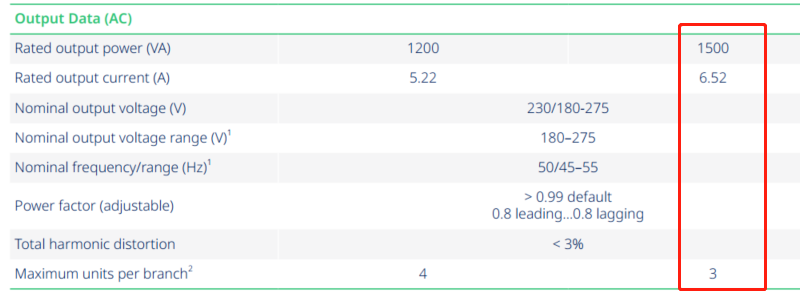

In order to find out this information, you can check the column listed as “maximum units per branch” on your microinverter datasheet, which specifies how many microinverters can be connected in a single branch circuit.

For example, in the case of Hoymiles’ HM-1500 microinverters, the maximum number is three. This means that if you have more than three microinverters, you’ll need to connect more than one branch circuit, instead of connecting all your microinverters together on the same one.

The rationale here is this: Your microinverter’s rated output current must be smaller than the rated current of the output terminal.

Let’s also take Hoymiles’ HM-1500 microinverters as an example here:

Our user manual states that the output current of our AC terminal is 25A, the rated output current is 6.52A, and there are three microinverters allowed in a single branch.

So the total output current is 6.52A × 3 = 19.56A, which is smaller than 25A. If you installed four microinverters, then the total output current would be 6.52A × 4 = 26.08A; as this is over 25A, this would increase the failure risk of the terminal.

Daisy chain connections

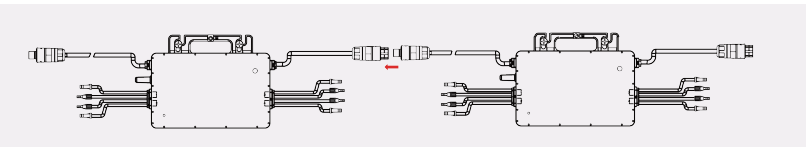

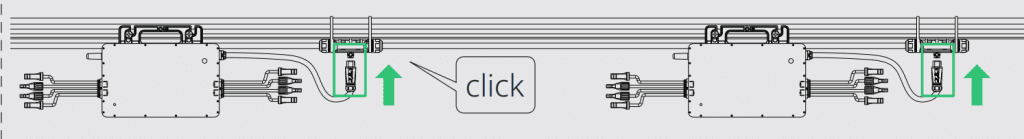

Microinverters can normally be connected in a single branch circuit. The single branch circuit that we can usually connect to microinverters is called a “daisy chain connection”; as shown in the picture below, the AC outputs of the microinverter are directly connected together.

However, in circumstances where you’re connecting high-powered microinverters, it’s considered bad practice to use a daisy chain connection. This is because it can present serious overload risk, which may result in the failure of the terminal. To avoid this, it’s crucial to follow our steps above to ensure you’re using the correct number of branch circuits for your chosen number of microinverters.

Trunk connections

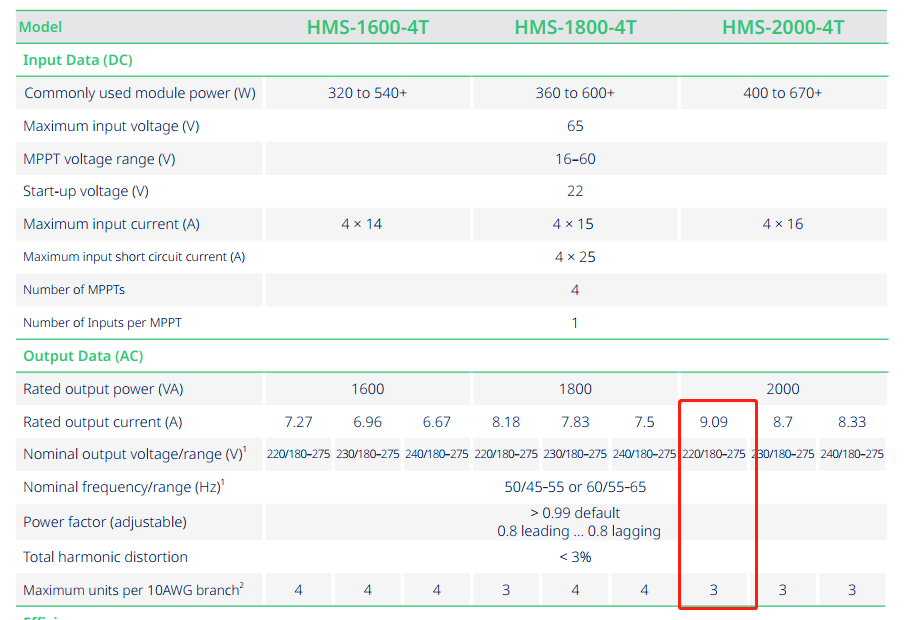

At Hoymiles, we also offer trunk connections for our new HMS microinverter series. With trunk connections, instead of directly connecting microinverters together, we connect each microinverter to an AC trunk cable via trunk connectors (as shown in the green boxes in the image below).

A trunk connection uses an independent trunk cable, so it’s less likely to create electromagnetic interference in the microinverter, and is much better for heat dissipation.

When it comes to installation, our installation expert would plug the output terminal into the trunk connector on the AC trunk cable.

Let’s use an example to illustrate this:

In the case of Hoymiles’ HMS-2000 microinverters, we recommend three units per branch.

If we set 9.09A as an example, the total current on the branch would be 9.09A × 3 = 27.27A, the rated current of the output terminal is 12A, and the rated current of our trunk connector is 30A.

We can see that 27.27A < 30A, so such installation is safe and will not cause any overcurrent.

Safety first with Hoymiles

While daisy chain connections can work well for lower amperages, they can be risky when using high-powered microinverters. If the microinverter manufacturer gives an inappropriate recommendation regarding the number of units that is acceptable for one branch circuit, there can be potential risks of terminal failure.

Hoymiles’ installation recommendation is sensible and safe, so you don’t need to worry about terminal failure. While some manufacturers may use alternative connections such as a Daisy Chain, we will always recommend a trunk connection in the case of high-powered microinverters.

Our high-powered HMS microinverters range from 1,600W to 2,000W in capacity – and all of them are connected via a trunk cable as standard.

Choose Hoymiles; choose open energy and safety for all.