Setting a new standard for green commercial buildings with a 2.65 million kWh capacity solar PV system

| Project Name | Region | Project type | Products | Size |

|---|---|---|---|---|

| Hangzhou Northern Software Park | Hangzhou, Zhejiang | Commercial/BIPV | HMS-2000-4T microinverters | 2.789 MW |

Can an entire industrial park overcome its challenges and embrace solar energy, even when the design of its buildings makes the whole project seem impossible? And how do you deliver large-scale energy savings and reduce emissions for a site of this size without compromising on safety?

In one of our biggest projects to date, Hoymiles designed an inventive and highly effective 2.789 MW BIPV installation for a commercial office building complex, not only tackling its principal energy challenges but also addressing some of its other persistent problems along the way.

Bird’s-eye view of the Hangzhou Northern Software Park

Their Story

Meeting the high energy demands of a tricky office complex

In Hangzhou, China, the Northern Software Park is at the heart of a cutting-edge digital economy industry cluster, dominated by sectors like IT services and digital cultural tourism. With its high levels of energy consumption and power demands increasing day by day, the park’s managers were keen to switch to a clean, renewable energy source as forward-thinking as the rest of its ethos – and one that would keep its spiraling electricity costs under control.

But there was a problem. The park’s ambitions were held back by challenges in the physical design of the buildings. The office roofs struggled with water leaks, and the buildings had high mechanical floors. A traditional power plant setup would provide the power the site needed, but wouldn’t do anything to help with the leaks. Equally, the buildings’ high mechanical floors created a lot of shade, which would interfere with the performance of a traditional PV system. That would result in less solar energy production, with poor efficiency and a smaller system capacity.

Clearly, the team had their work cut out to design an installation that would work.

Their Solution

A high-power, high-performance strategy

Expert knowledge to tackle nuanced challenges

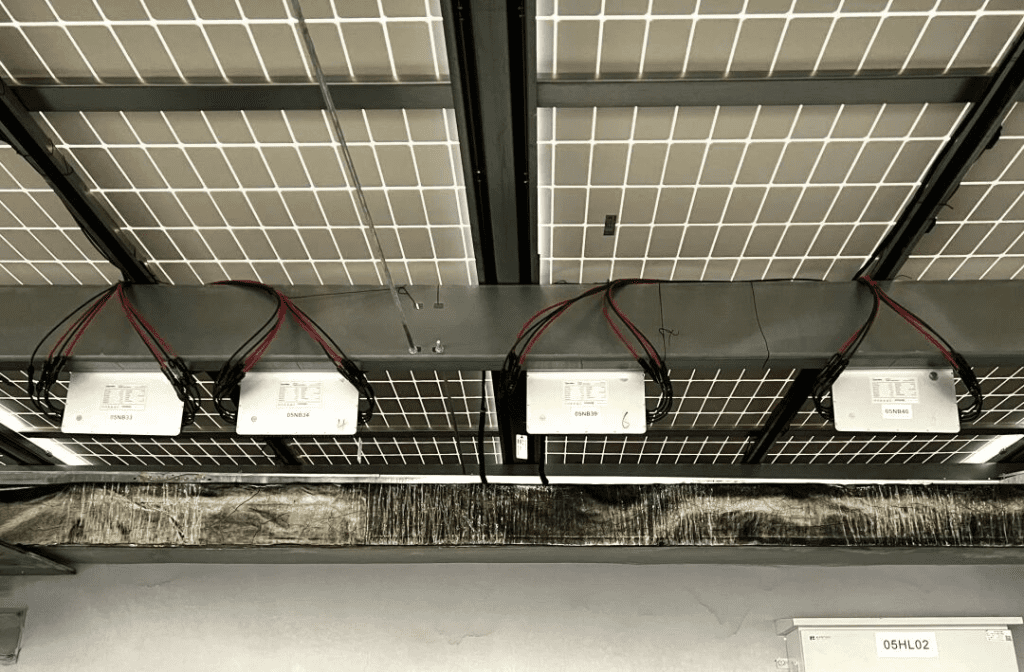

But using a BIPV model creates its own challenges. These systems have higher performance requirements than normal solar PV power stations. That applies especially to the system’s inverters. Plus, with a BIPV model, you need to integrate the photovoltaic system with the building itself. This makes ensuring safety in the BIPV especially important, as any issues will increase the risk of fire.

Again, the team knew exactly what the model needed: microinverters.

Supercharged energy efficiency

Not only do these increase power generation and make the whole system more efficient, but the super-reliable Hoymiles HMS-2000-4T microinverters make operations and maintenance more effective and intelligent.

That’s partly because Hoymiles microinverters have wireless connection and monitoring features that link to the S-Miles Cloud platform – giving technicians full oversight of what’s happening inside the system in real time. These insights include how much electricity is being produced and used; the voltage, current, and power of the system; and real-time information about any problems that might crop up. The team are able to tweak and improve the system where required, keeping the system as productive and efficient as possible and reducing maintenance costs.

… Plus, these microinverters have an output power of up to 2,000 VA. Combined with MPPT technology and precise, module-level control, this offers plenty of ways to optimize green energy production safely and effectively for the park.

Eliminating safety risks

Even better, Hoymiles microinverters are also designed to maximize system safety.

That’s because the technology allows each PV panel to be connected independently to the microinverter. With conventional inverters, the DC circuit voltage can shoot up into the hundreds or thousands, which can become extremely dangerous. Hoymiles’ approach, on the other hand, means there is no voltage stacking between modules, and the DC circuit in the system will stay under 60 V all the time.

This eliminates the risk of fire or electric shock that might otherwise be created by DC arcing in the system. It also makes sure the system meets global rapid shutdown regulation requirements.

Their Success

Leading the way for safe and efficient renewable energy development at scale in Zhejiang, China.

Optimal energy production with a perfect safety record

For the Hangzhou Northern Software Park, the benefits of this system have been enormous.

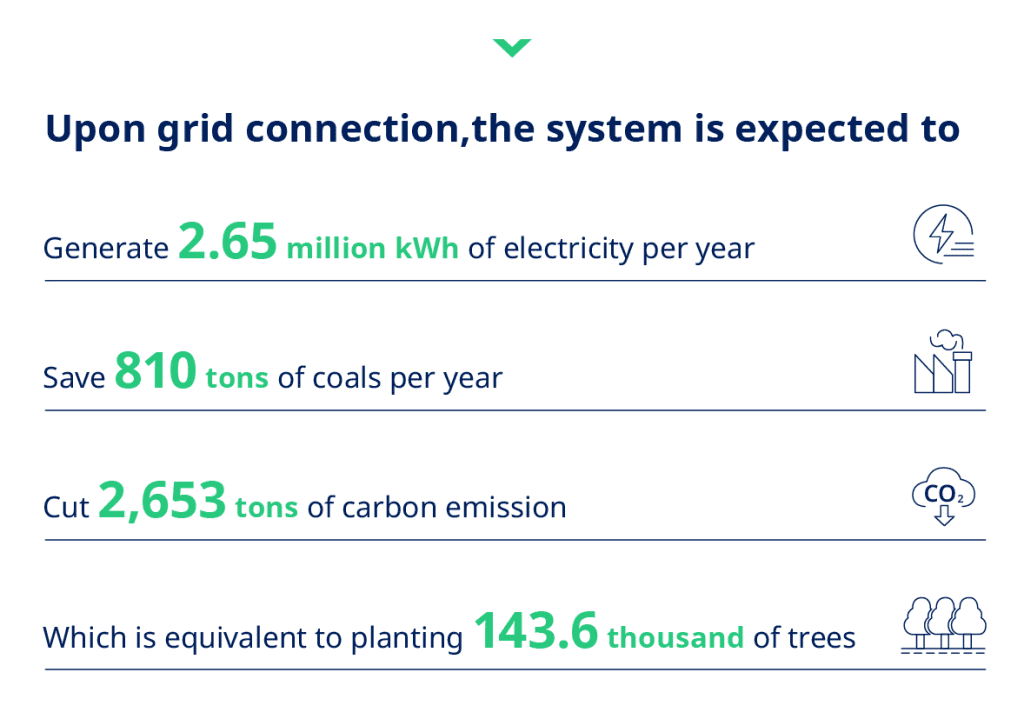

Following its completion in late 2023 and connection to the grid, the project is now capable of generating approximately 2.65 million kWh of electricity every year.

That’s the equivalent of burning 810 tons of standard coal, but in this case, it’s all clean, green, cheaply produced solar PV electricity.

Which also means the park has reduced its annual carbon footprint by 2,653 tons – or the equivalent of planting 143,600 trees.

Plus, it’s all been achieved in a safe, reliable way that reduces energy costs. The solar system has even found ways to fix pesky problems in the buildings’ structural design at the same time. Truly a winning outcome from every perspective.