Hoymiles Microinverter Reliability Explained: Our Extensive Warranty that Covers Your PV Lifecycle

Photovoltaic (PV) inverters are responsible for converting the DC power captured by solar panels into AC power, and they play a key role in any solar setup. In fact, the efficiency of your inverter largely determines the efficiency and performance of your entire system.

Hoymiles microinverters are exceptionally reliable, even in the most challenging environmental conditions. They are designed to operate two to four times longer than traditional string inverters, lasting throughout your system’s lifecycle.

But how do we achieve such optimal microinverter performance? The short answer is that our R&D team focuses on ultimate reliability from the very beginning of product development: including PCB design, component selection, supplier selection, regional certification tests, and our rigorous reliability tests. The long answer is…Well, let’s read on to discover the rugged technology that makes Hoymiles microinverters the robust powerhouse of your PV universe.

An Extended Warranty to Get Your Solar Covered

You might have heard about the two most common types of solar inverter: string inverters and microinverters. While the former transforms power on a per-string basis, the latter does so for each individual panel.

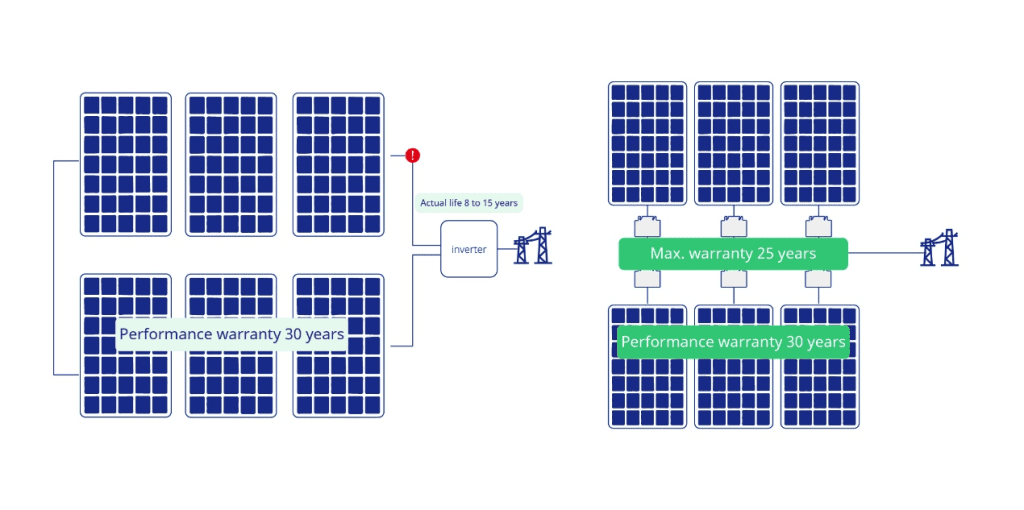

While the performance warranty for PV modules using string inverters can be as long as 30 years, string inverters themselves are generally designed with a 15-year service life in mind. Depending on the inverter design, the materials used, and the installation environment, their actual typical life ranges from 8 to 15 years. So there’s a problem here: There is a 2-4 times lifespan difference between the two. In a real-life scenario, this means that string inverters are likely to need replacing halfway through the service life of the PV system.

In comparison, the design life of Hoymiles microinverters is much longer than that of traditional string inverters, with a maximum warranty of up to 25 years. This ensures that the life span of the microinverters matches that of your PV modules, making the subsequent operation and maintenance of the PV system more convenient and cost-effective.

The IP67 Hi-level Protection Test

In order to ensure the absolute protection of our microinverters against dust and water, Hoymiles redesigned their internal layout and adopted a potting compound-based comprehensive sealing method.

As a result, all our microinverters are certified with an IP67 rating, meaning that they can resist the force of water hoses and jet sprays, and tolerate submersion in water of a depth between 150mm to 1000mm for up to half an hour. Microinverters with an IP67-rated enclosure are assured to operate effectively in indoor and outdoor environments, as well as in challenging industrial and commercial situations.

Mechanical Environment Testing of Hoymiles Microinverters and Their Components

When sourcing microinverter components, we require our suppliers to conduct a series of stringent tests. To meet critical performance and reliability requirements, Hoymiles also carries out extra tests either in our own labs or via independent third-party testing institutions.

Additionally, Hoymiles microinverters are put through a series of rigorous vibration, shock, and drop tests to simulate the mechanical environment that microinverters may experience during transportation and installation.

All the above test results are compliant with IEC 62093:2022.

Highly Accelerated Life Test

Hoymiles puts our microinverter prototypes through Step-up Performance Testing to identify potential design flaws and weaknesses. By exposing the product to extreme temperatures and vibration conditions, our engineers can improve the technical design long before the product reaches the market. This includes extreme high- and low-temperature cycling, high-level vibration testing, and comprehensive environmental stress testing. (IEC 62093:2022 / IEC 60068-2-38)

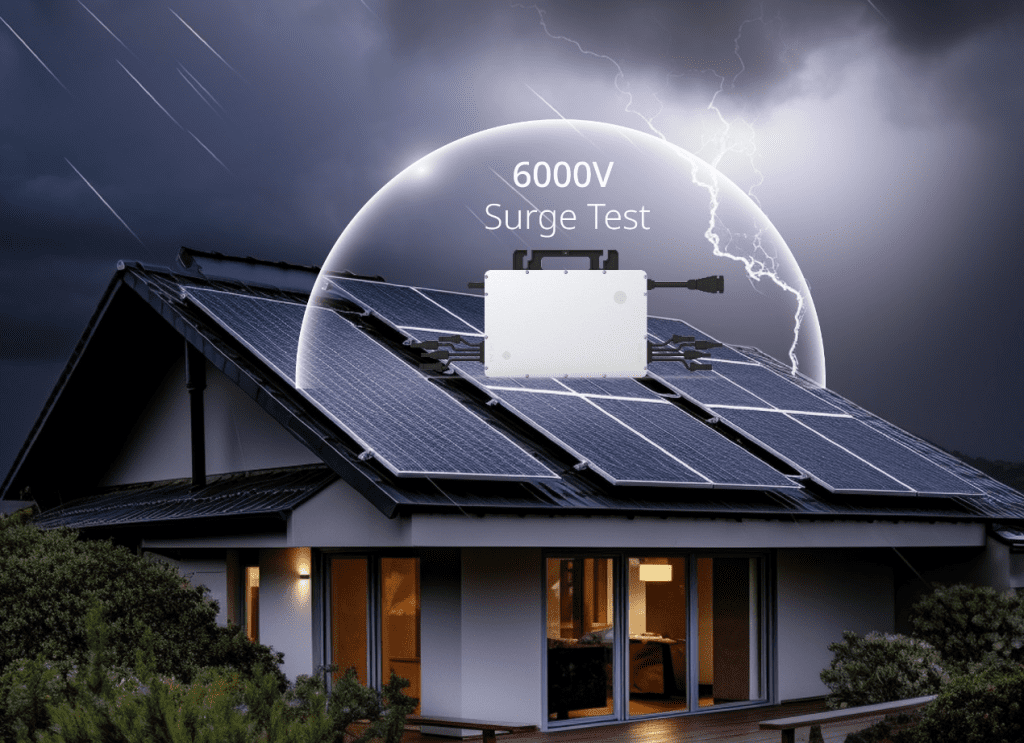

Enhanced Lightning and Surge Test

To further ensure that our microinverters are compliant with safety standards, Hoymiles R&D carries out lightning tests. A signal generator is used to produce a 6000V surge voltage: after multiple tests, the microinverter unit must not show any abnormalities in order to pass.

The threshold requirement stipulates that any microinverter withstanding a 2000V surge test (Category III) receives a green light. But Hoymiles has chosen the much stricter 6000V surge test for our microinverters (Category IV), making our products globally compliant and offering more options for customers. (IEC 61000-4-5:2014)

The strength of this testing means Hoymiles microinverters can make a real difference to your solar setup. In addition to a sudden voltage surge from the grid, PV systems may also experience lightning during bad weather. A lightning strike can pose high voltage and electric shock risks, so it’s essential that your system components are strong enough to deal with these rare situations.

Our standard makes sure your whole system will not malfunction even if the lightning protection measures of your property/building fail and a voltage surge strikes the microinverter directly.

Category III (CAT III) and Category IV (CAT IV) are safety standards for electronic devices like your home electricity meter. These standards are there to make sure the devices are safe to use.

CAT III: This level is for devices that are used inside the home. For instance, the outlets and switches on your walls fall into this category.

CAT IV: This is the highest standard level and mainly applies to devices directly connected to public power lines. For example, the equipment outside your home connecting to the utility company’s line would fall under CAT IV. These devices face more risks because they are prone to current and voltage shocks from the grid, which is why higher standards are applied.